Environmental Activities

MJC recognizes the importance of corporate responsibility when it comes to protecting the planet, which is why we are continuously taking part in environmental activities such as reducing resource and energy consumption, reducing waste, advancing recycling processes, and ensuring appropriate management of chemicals.

Our Energy Use

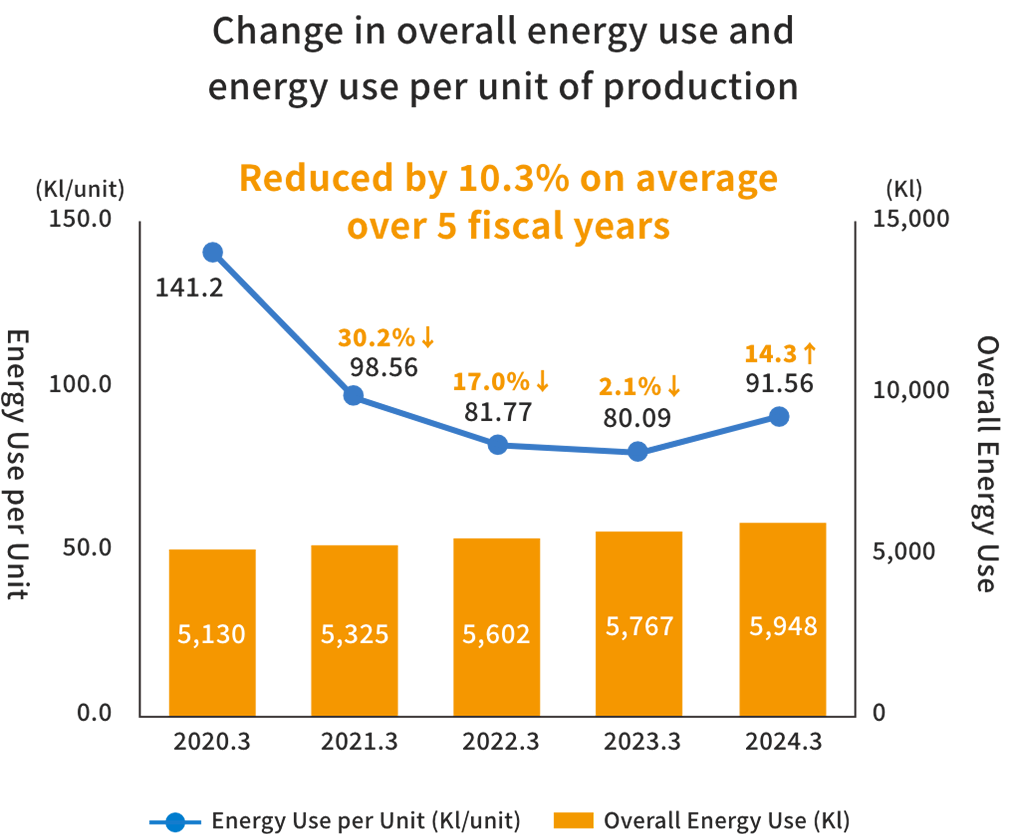

At MJC, we monitor the energy usage of all domestic business operators and work to reduce energy consumption per unit.

In 2023, our energy usage increased by 17.2% compared to the previous year due to higher air conditioning loads caused by the rise in average summer temperature and the expansion of production facilities. However, we successfully reduced energy consumption per unit by an average of 11.1% over the five fiscal years from 2019 to 2023.

However, that isn't the end of the line. We continue to challenge against global warming by finding ways to further reduce per unit energy usage and conserve energy.

*1: Energy consumption per unit: representative figure of energy efficiency. The lower this figure, the more efficient the production, saving energy and contributing to efforts against global warming. (MJC is continually tracking its energy consumption against production figures.)

| CY2019 | CY2020 | CY2021 | CY2022 | CY2023 | Average yearly change in energy consumption per unit (2019-2023) *² |

|

|---|---|---|---|---|---|---|

| Overall Energy Use (kl) |

5,031 | 5,279 | 5,449 | 5,792 | 5,885 | |

| Energy Use per Unit (kl/unit) |

150.6 | 104.2 | 81.09 | 80.17 | 93.98 | -11.1% |

*2: Average yearly change in usage per unit in %: Figure shown represents change based on usage figures of any given calendar year compared to the preceding calendar year where it is set at 100%.

Appropriate Management of Chemicals

Chemical materials that MJC uses are fully managed in accordance with all relevant regulations.

Before the induction of any chemical material, risk assessments are carried out to evaluate levels of possible danger to human health and in turn set up measures to deal with such risks.

In addition, we have set up a chemicals registration system, allowing us to manage the quantity of any given chemical being used and apply the appropriate regulations according to each division. This is MJC's compliance evaluation procedure to ensure the appropriate management of chemical materials used.

Effluent treatment system

At the Aomori Plant of MJC, we have introduced wastewater treatment equipment so that wastewater discharged from the manufacturing process does not impact the environment. We discharge treated water that has gone through a process such as cohesion and precipitation into the sewage.

In addition, since gold and other precious metals are used in the production of probe cards, these are collected from wastewater for recycling.

Additionally, Aomori Factory has come up with a way to employ a cooling system that uses natural outdoor air in cleanrooms where it manufactures probe cards.

The introduction of these kinds of cutting-edge systems has not only reduced environmental impact compared to the systems that MJC used to use, but has also led to cost savings.